|

Hydraulic circuit End cap made from 12L14 steel and nickel plated. Produced on a 8 axis lathe.

Hydraulic circuit End cap made from 12L14 steel and nickel plated. Produced on a 8 axis lathe.

Electro-Mechanical actuator motor Cap. Made from 2024 Aluminum with chromic anodize finiish.

Electro-Mechanical actuator motor Cap. Made from 2024 Aluminum with chromic anodize finiish.

Pressure sensor component made from titanium.

Pressure sensor component made from titanium.

Medical instrument component made on multi axis lathe from 2024 aluminum.

Medical instrument component made on multi axis lathe from 2024 aluminum.

Electromagnetic servo valve component with internal circuit precision deburred under magnification.

Electromagnetic servo valve component with internal circuit precision deburred under magnification.

Heat treated stainless steel actuator component ready for helicoil inserts.

Heat treated stainless steel actuator component ready for helicoil inserts.

Heat treated stainless steel hydraulic valve end cap with internal circuitry precision deburred under 45x magnification.

Heat treated stainless steel hydraulic valve end cap with internal circuitry precision deburred under 45x magnification.

Motor cap made complete on multi axis lathe from 6061 aluminum with an anodize finish and chemical conversion coating.

Motor cap made complete on multi axis lathe from 6061 aluminum with an anodize finish and chemical conversion coating.

Medical instrument panel with anodized finish and laser etched printing.

Medical instrument panel with anodized finish and laser etched printing. Valve cover made from 6061 aluminum with blue anodized finish.

Valve cover made from 6061 aluminum with blue anodized finish.

Electrical assembly cap produced from 6061 aluminum in high production quantities.

Electrical assembly cap produced from 6061 aluminum in high production quantities.

Electrical connection cap made on horizontal machining center.

Electrical connection cap made on horizontal machining center.

Optical assembly component

Optical assembly component

Actuator motor cap

Actuator motor cap

Chemical filter test body

Chemical filter test body

Optical component made on horizontal machining center.

Optical component made on horizontal machining center.

Refractometer body made complete on multi axis lathe.

Refractometer body made complete on multi axis lathe.  Oxygen valve body made from aluminum forging in single operation on horizontal machining center.

Oxygen valve body made from aluminum forging in single operation on horizontal machining center.

Electro-mechanical rod end made from heat treated 4140 steel.

Electro-mechanical rod end made from heat treated 4140 steel.

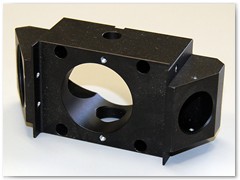

Microscope multi-viewer body made from 6061 aluminum with anodize and powder coated finish.

Microscope multi-viewer body made from 6061 aluminum with anodize and powder coated finish.

Motor cap machined complete from 6061 aluminum bar stock.

Motor cap machined complete from 6061 aluminum bar stock.

Medical instrument valve body.

lightbox js web gallery generatorby VisualLightBox.com v6.1

Medical instrument valve body.

lightbox js web gallery generatorby VisualLightBox.com v6.1