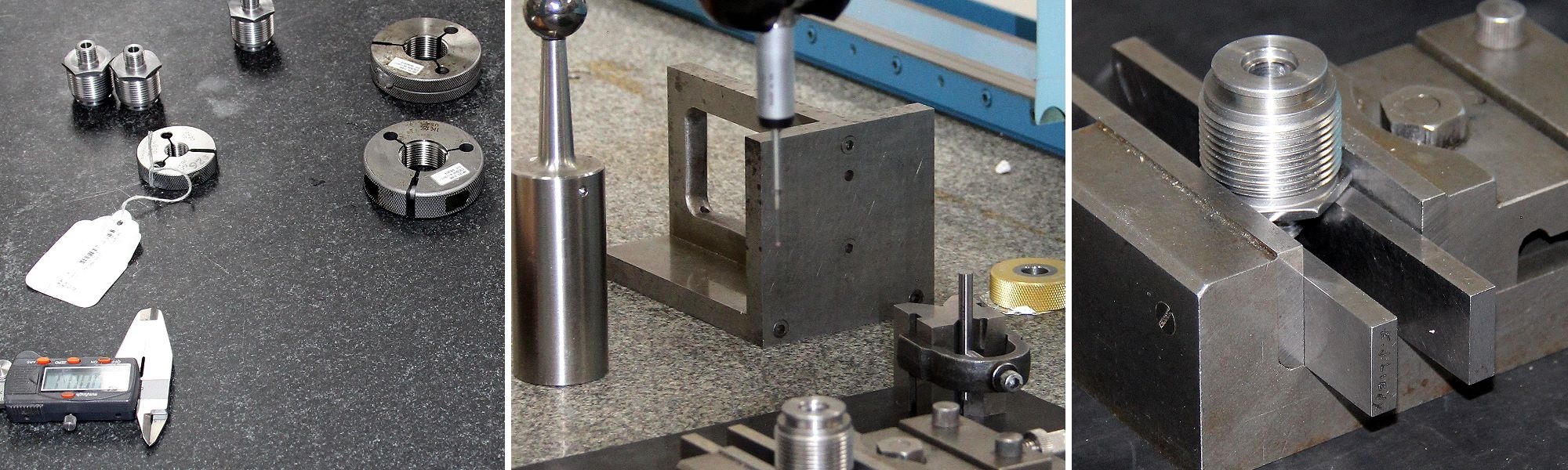

| Contract OEM Machining and Assembly of Complex, Tight Tolerance Components

Building on a history of tight tolerance machining for tool and die applications, Muller today applies that same commitment to precision machining to providing complex, highly specified, small size OEM components and sub-assemblies. We specialize in aluminum alloys, but work with the full range of ferrous and non-ferrous alloys. The items we produce are used in precision equipment in aerospace, defense, medical, optical, measurement and industrial applications.

Benefits of Outsourcing to Muller Precision

-

Maintain on-time delivery with order surges

- Fill in production gaps created by personnel shortages

- Continue growing as you reach internal capacity limits

- Handle on-shoring of production formerly done outside the U.S.

Flexibility to Fit Where You Need Us

We invite companies to partner with Muller as an extension of their operations. We are flexible to fit into your value stream where it makes sense.

- Low to high volume production

- Tolerances to 0.0001 inches

- Prototypes

- Value engineering

- Design assistance

- Material selection

- Partnering during production startup

- Heat treat

- Paint / E-coatings

- Plating Anodize / Electrochemical treatments

- Assembly, final finishing and labeling

- Inspection

- Packaging

- Kanban and Drop shipment

- Inventory management

Equipment

In addition to our range of capabilities in horizontal and vertical machining, multi-axis turning, and grinding, listed below, we also have capabilities for meeting requirements for mil-specs, traceability of materials and heat codes, and XRF (X-Ray Fluorescence) testing of materials.

CNC Machines

- Mori Seiki NLX 2500 CNC Mill-Turn Center

- Mori Seiki NHX-4000 Horizontal Machining Center

- Mori Seiki NZ-2000 T2Y2 8 Axis Lathe

- Mori Seiki NH-4000 Horizontal Machining Center

- Mori Seiki SH-400 Horizontal Machining Center

- Okuma 4VA Vertical Machining Center – 2

- Howa Vertical 2 Pallet Machining Center

- Puma 240 Lathe with Milling and Bar Feed

- Lynx 220 Lathe with Milling and Bar Feed

- Mazak QT6 Lathe with Bar Feed

- Okuma LB15 Lathe

Manual Machines

- 15" Lathe

- Bridgeport Mill – 4

- Horizontal Surface Grinding

- DoAll 11″ Horizontal Production Saw

- Assorted Manual Machinery

- Vibratory Tumbler

Quality System

Muller Precision is ISO 9001:2015 certified and our Quality Assurance department complies with MIL I-45208A and other industry standards and accepted practices.

|